Blue Printing Oil Pump

Illustrations below taken from Factory Shop Manual

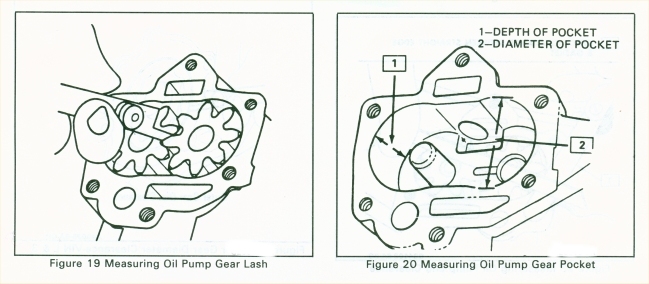

Lash specs: 0.0015-0.003" 0.038-0.076mm Depth: 0.868-.0870" 22.04-22.10mm

Diameter: 1.670-1.675" 42.4-42.5mm

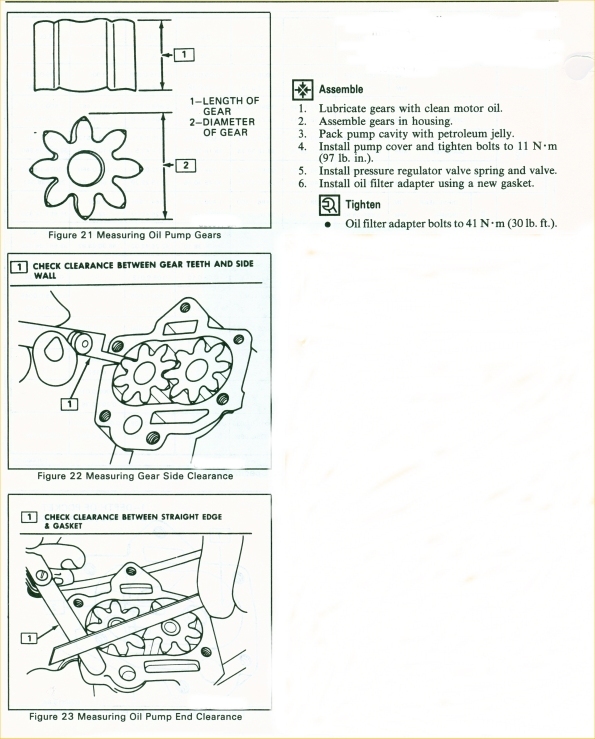

Side Clearance (Drive Gear) 0.003-.005" 0.08-0.013mm (same for Idler Gear)

End Clearance 0.002-0.006" 0.05-0.15mm

There are a couple of ways to approach it.

1) you can omit the gasket and lay a straight edge across the

pocket over the gears and measure the clearance. Then take this clearance

and determine what thickness of gasket is required to give you the 0.002-0.0025"

that you desire. Look at the picture just above to see how straight edge is laid across the gears.

2) you can lay the gasket in place, put the straight edge on top of the gears as shown above, and measure the clearance to see if it gives you an acceptable number.

If you have to shorten the gears, or the pocket, be sure to use a heavy piece of plate glass and some wet or dry sandpaper so that the pieces stay true to each other.

After you finish getting it to your satisfaction, get it clean and don't then add any form of gasket sealer to the gasket. Did I mention CLEAN?

If you are using new gears, take a fine file and slightly chamfer the edges of the gear teeth, top and bottom. Sand the gear teeth lightly with some wet or dry paper to remove any flash or rough spots. Again, clean them up well!

TA Performance sells gasket sets of varying thickness in order to bring the end clearance to the desired point. I suggest close to 0.002" is preferred. I would start with the GM gasket as I think it tends to leak less.

Altho' we tend to concentrate on end clearance, Robert Carruth, who worked for the GM engine division, posted that the side clearances were really the most important. Others state that the end clearance is more important. I don't know, but, why not check them both? TA Performance also sells oil pump parts as well as the the plate kits. Most auto parts stores carry the plate kits as well. It's pretty common for the stock cover to become worn. It's aluminum and time and trash wear on it. You don't want to use a cover that is grooved.

With regard to high volume covers and gear sets, I do not believe they are desirable, or required, if the clearances in the engine are within bounds.

Why not? Okay, first thing that happens is that on a cold start, the engine cannot deal with the volume of oil that is pumped and it will blow the bypass valve open thereby circulating unfiltered oil back to the engine. Plugged the bypass? Okay, it tries to crush the filter medium. Yeah, I know your boy down the street says there is no problem. Wonder why he is always rebuilding engines?

Then we have the simple fact that it takes more hp to turn the pump and the effort to do so puts a strain on the front cam bearing and the drive rod. Front cam bearing wears and the oil pressure starts bleeding off at the bearing leak. (I think too stiff valve springs aggravates cam bearing wear also, but, that's another topic.)

Now, if you buy a new front cover, many of them have passages obscured by casting flash-even the ones from GM. Eyeball them carefully and remove any bits of flash or obstruction. I think my Power Source manual is in Houston so I am not going to attempt porting instructions from memory. I don't think it really required on a 5000-6000 rpm engine, anyway. Just get the passages clear and the corners rounded if you have something to do that with.

This will save you from taking things apart later down the road when the engine refuses make oil pressure when you try to prime it.

Another tip, if you do an oil pump for any reason, it will not hurt to pull the pan and check the pick up. Be sure it is tight and be sure it is not covered with nylon debris from the timing gear or some other type of debris. A loose pick up will suck air and will cause heartache down the line. A blocked screen will cut the oil flow. The T that I bought was low on oil pressure. I pulled the pan and found what looked like the remains of a shop rag wrapped around the pick up. Oh, yeah, if you use the factory pan gasket, use a torque wrench and follow the factory specs....I did three one day, before I learned this little fact.

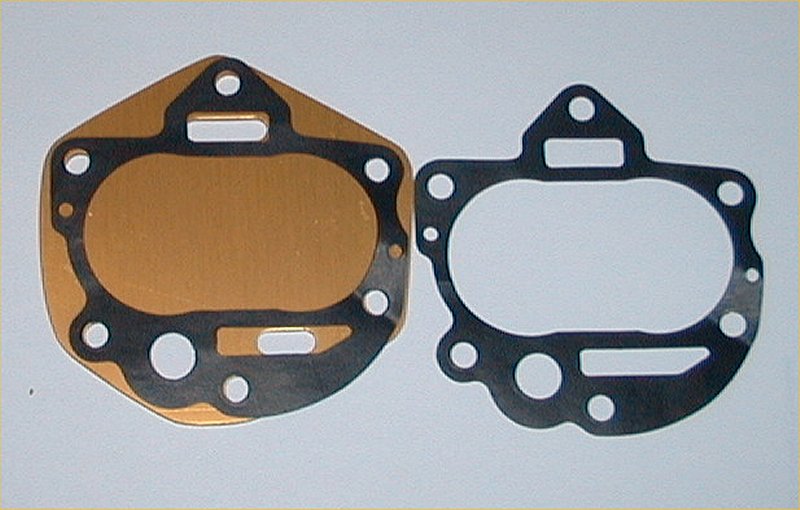

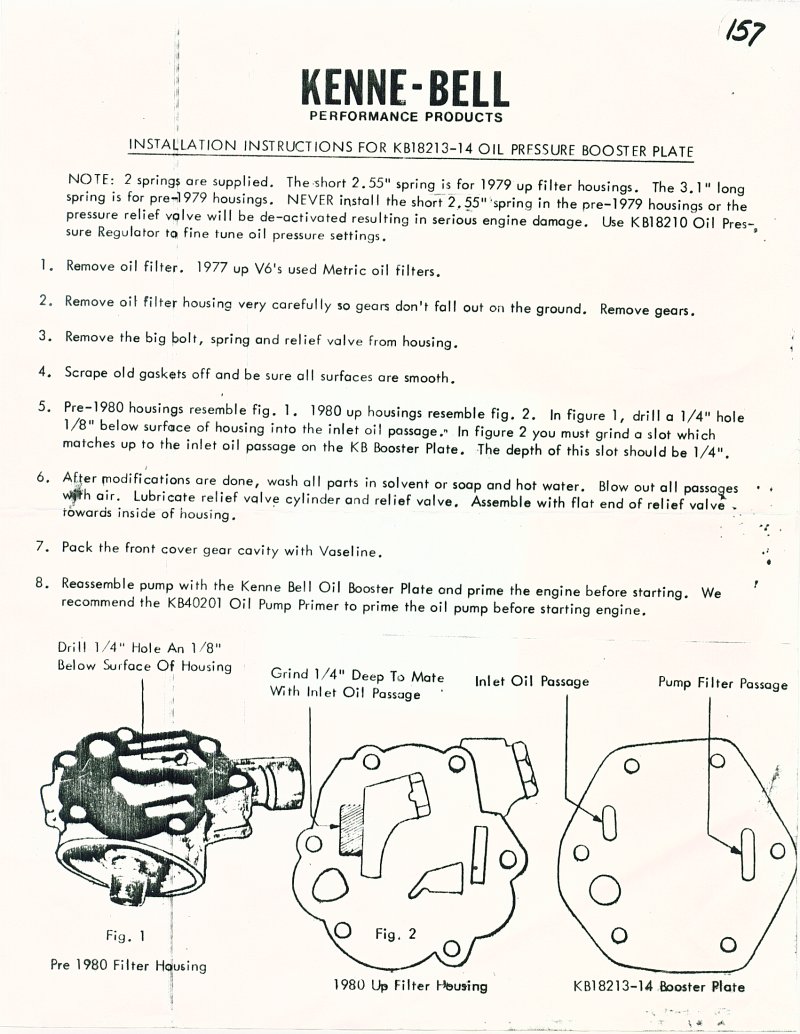

I am not going to discuss booster plates in detail as I think they vary in installation and the only one I have seen/have is from Kenne-Bell (see pictures below). Just follow the instructions that come with the kit. I believe they are a preferred alternative to the long gears/high volume covers.

These engines can be difficult to prime as the oil pump is not submersed in oil. Packing the cavity in vaseline is the time honored means. You can also disconnect the outlet line to the oil cooler and pour oil down it which will fill the cavity and make it start to suck from the pick up when the pump turns. Tight clearances on the end of the gears and the side pockets encouraging priming as well.

If you are doing this in the car with the cam sensor installed...watch the oil pressure gauge when you crank the engine. It should prime virtually instantly. If it does not, get it primed before you start letting the engine run! You do have an oil pressure gauge, right?

One final topic in this discussion. A few suggest that the bypass valve in the front cover should be plugged so that oil must always pass through the oil filter rather than potentially allowing it to be bypassed on start up when the oil is cold and thick. This is one of those ideas that sound good, but, may be dangerous for the average person that may live in a colder climate or has a tendency to drive the car before the oil has warmed up (this is 99% of us). It is quite common for the filter media to be crushed when the engine is first started when the oil pressure tries to push cold oil thru the filter media. Having a high volume cover will only make this likelihood greater. This is one of those ideas that sounds good, but, can lead to severe damage if it goes wrong. Leave it to the race car guys that want to try it. Don't believe that some filters are bullet proof to excessive pressure. Note, there are a few filters out there with bypass valves built in that have higher bypass reliefs than the factory set up. See my comments in the Tech Picture section on Front Covers.

That takes us to oil weights. Use 10W30 weight oil as long as it will maintain 12-15 psi oil pressure at idle in Drive after a hard pass on a hot day. There is no need to use a heavier oil unless the idle pressure, or the wot pressure, is low when the oil is hot after/during a hard pass. Lighter oils were not suggested in normal situations by the factory so I don't like 0-30s or 5-30s either unless one is building a race engine that will be rebuilt frequently and the extra two horsepower are absolutely required.

Normally, if the engine will make 50-60 psi at wot on a hot engine, the idle pressure is not really crucial as there is no load on the engine at idle and 10 psi would not be a concern for major worry UNLESS it is normally 15-20 psi under the same conditions and suddenly has dropped.

Kenne-Bell Oil Pressure Booster Plate

Note that this plate goes between the Oil Filter Housing and the front cover. It requires longer bolts to prevent stripping the threads from the front cover. Some grinding is required as shown in the instructions below to the Oil Filter Housing. It's my opinion that these type plates should only be used on a stock front cover and not on a high volume cover.

Thinking about it, if the stock pump is not making enough pressure, I suggest finding out why rather than using one of these gimmicks.....